Gazpack Sulabead® 200 system

Sulabead® 200 system

The Sulaway® system is designed to upgrade large-scale amounts of Renewable Natural Gas (RNG). And for smaller capacities, Gazpack introduced the Sulabead® 200 system.

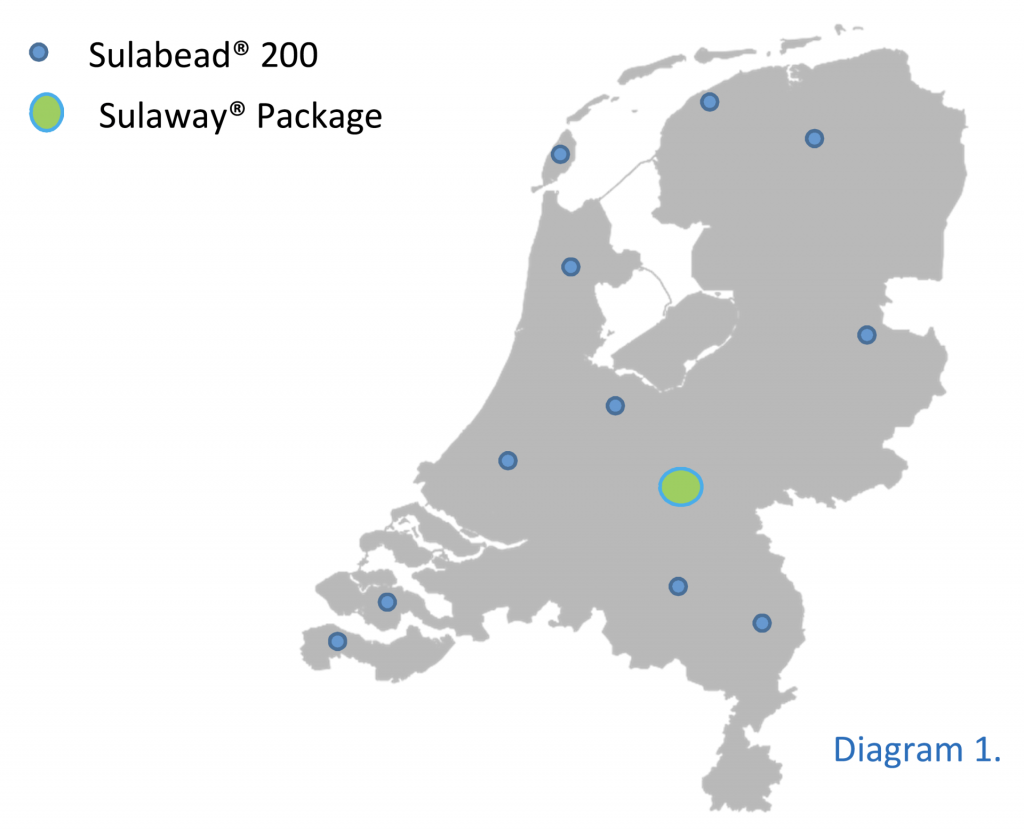

The Sulabead® 200 system is based on a cluster principle, meaning that several smaller units are placed at various locations collecting the RNG onsite. Once the Sulabead® tower is saturated, the tower is collected and transported to a central location where a Sulaway® package is situated to allow the RNG to be processed further. (see diagram 1)

The Sulabead® 200 system consists of one water separator, one compressor/dryer set and two Sulabead® filter towers, all of which are stored in one compact storage system. All of the Sulabead® stations are equipped with a gas leak alarm.

Process cycle

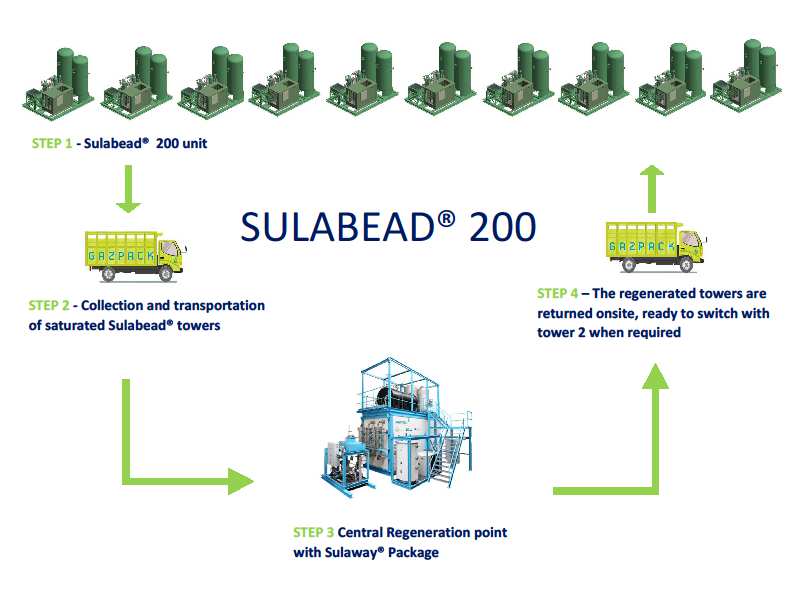

The diagram to outlines the four steps the system follows, the four steps are as follows:

- Step 1: The concept behind the Sulabead® 200 process is to be able to provide smaller, more compact and affordable Sulabead® units to individual locations, allowing their renewable natural gas (RNG) to be collected and partially processed.

- Step 2: Once the Sulabead® filter tower is fully saturated, it is transported to a central collection point.

- Step 3: At the central location point there’s one Sulaway® Package. Here the saturated towers are regenerated.

- Step 4: Once the towers are regenerated, they are transported back on site where the towers are then re-integrated back into the system.

At any given time, only one Sulabead® 200 filter tower will be in operation, actively monitored by an H2S sniffer. The other will be on stand-by mode. When the level of H2S collected reaches the pre-set amount an alarm will be triggered sending a message to the controller. The system will then automatically switch over to the second (stand-by) tower. A signal will also be sent to our head office, notifying us that the saturated tower is ready for regeneration and collection will be arranged.

Benefits

So what are the benefits of using the Sulabead® 200 system? Simply put the benefits are as follows:

Low maintenance

1. Low maintenance and operational costs (the Sulabead® 200 system is up to 15% cheaper than activated carbon)

No waste bi-products

2. This system has no waste by-products. All outgoing streams produced are completely re-usable or re-sellable! (Acid water can be collected and resold as a by-product of the process)

Improve 'green' image

3. Sulabead® 200 will improve your companies green image (With carbon you are left with a dirty adsorbent, which is unfriendly for the environment and unrecyclable. Sulabead® however, can be regenerated and is made of all natural and recyclable materials).

Standby safety purge system

A number of applications can be applied using our system, such as sludge from water treatment stations, organic waste, energy crops, landfill and much more. In short, anywhere where biogas is produced and stored, our system can be applied! The process of the Sulabead® and Sulaway® packages is environmentally friendly and sustainable! All outgoing products are reusable and energy consumption is low due to heat recovery.