Nitrogen purged stack Flow scheme

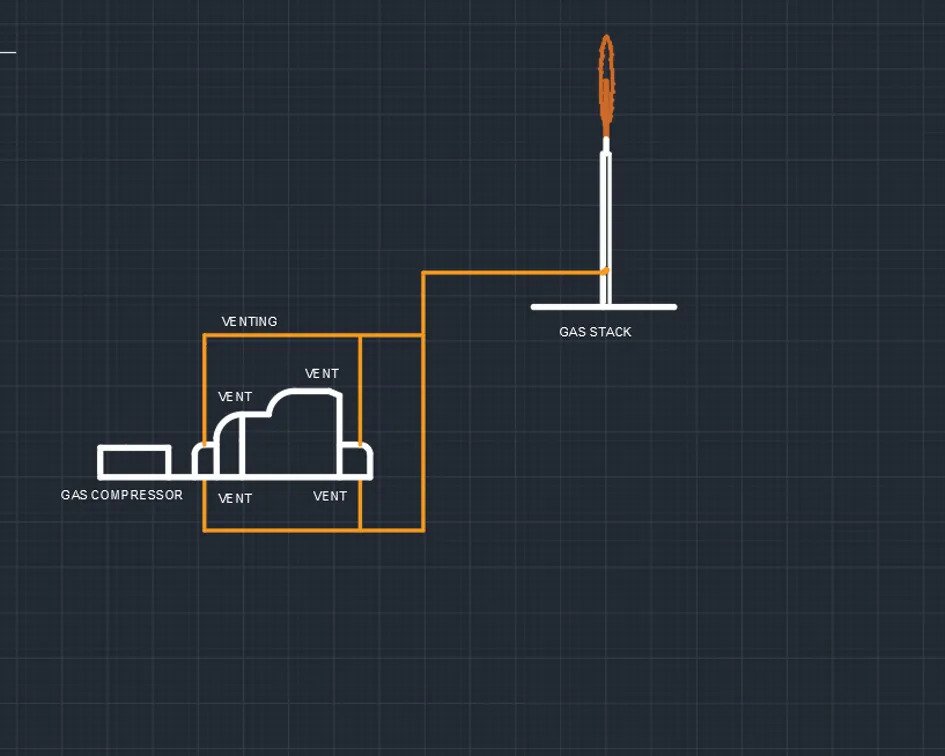

Gas compressors have a labyrinth sealing on both shaft ends to avoid gas leakage in to the atmosphere. On the contrary to mechanical seals – applied in pumps, diesel engines and most rotating machines – labyrinth seals are not leak proof. There must be constant venting of the system. For oil free air screw compressors, leakage of air is not harmful, but for gas compressors leakage of natural gas would be harmful to the environment. For safe operation, gas is fed into a stack at safe distance from the oil/gas platform.

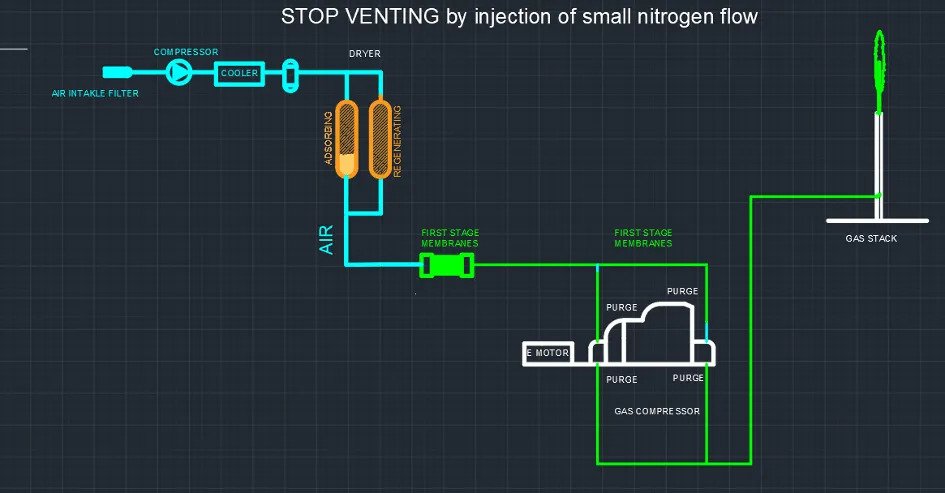

The solution to this problem is to shut off the gas purge and connect a nitrogen feed. This is a cheap solution as only small flows are required. The quantity of energy required for compressed air to produce nitrogen is less than gas lost in the compressor. So this is a win-win situation.

Airpack is supplier of complete (small) Nitrogen packages to improve the environment. The end result for gas companies is that they save on gas leakage, which means saving money but also improving their carbon footprint.