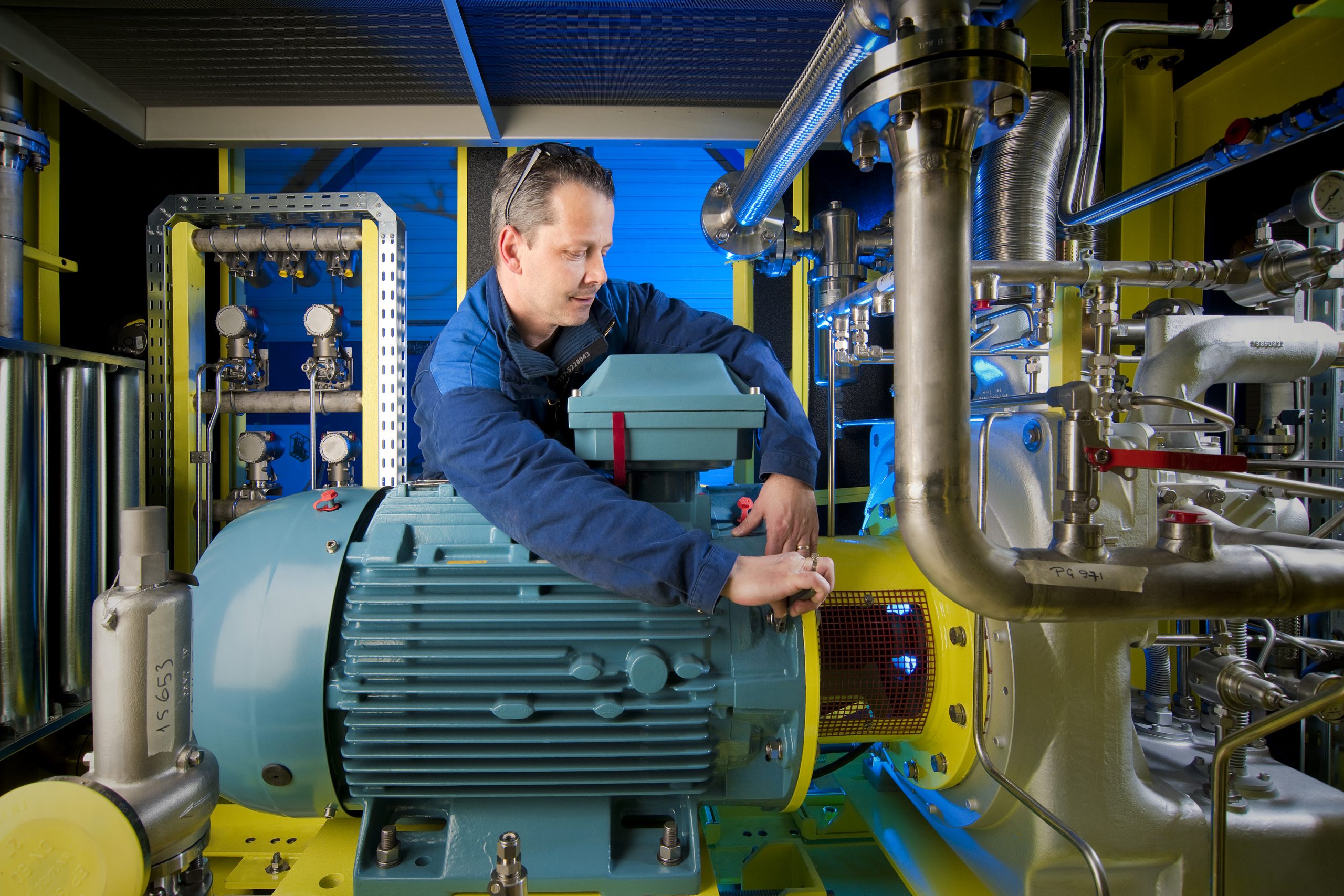

Custom made biogas upgrading solutions!

Delivering customer-specific biogas upgrading solutions for capacities between 100-5000 Nm³/h. Use our biogas calculator to find out how much clean gas you will produce with your substrate.

What is Biogas?

Biogas is a mixture of gasses that is formed by the digestion of biomass (i.e. manure or organic waste). Seeing as Biogas is a result of digestion of natural sources, it is a renewable energy source. Natural energy sources such as biomass will never run out and there is no pollution such as greenhouse emissions.

From Biogas to Biomethane

The two main components of Biogas are Methane and Carbon Dioxide, but it also contains sulfuric acid and water. To convert biogas into biomethane, a renewable natural gas (RNG), all the above components must be removed and separated. With our patented Sulaway® upgrading system we are able to convert small- and large-scale capacities of raw biogas into several usable products: RNG, CO₂ and Sulfuric-acid. For example, CO₂ can be captured and used in the agricultural industry.

2 days of maintenance per year

With our proven membrane technology, Gazpack can deliver high quality renewable natural gas (RNG). As opposed to other alternatives such as activated carbon, which require maintenance every 4-6 weeks, our Sulaway® technology needs on average two days of maintenance annually. Due to low maintenance costs, a higher profitability can be achieved. Moreover, our system runs almost the entire year resulting in a higher gas yield!

Expertise

As a daughter company of Airpack Netherlands, sophisticated challenges will be handled with experience and expertise.

No waste products

Our Sulaway® system has no waste products. All outgoing streams are completely re-usable or re-sellable (i.e. battery acid)

Low maintenance

Sulaway® only needs 2 days of maintenance shutdown per year and is far cheaper than usage of active coal.

Customer-specific

Our patented Sulaway process can be used for a wide variety of capacities. From 100 Nm³/h up to 5000 Nm³/h.

The replacement of natural gas with biogas is such an important contribution to sustainability. For our customers this means they can create a positive image and impact in contributing to the improvement of our green planet.

Piet Warnar - President Airpack / Gazpack

This project was made possible by a contribution from the European Regional Development Fund as part of OP-South.